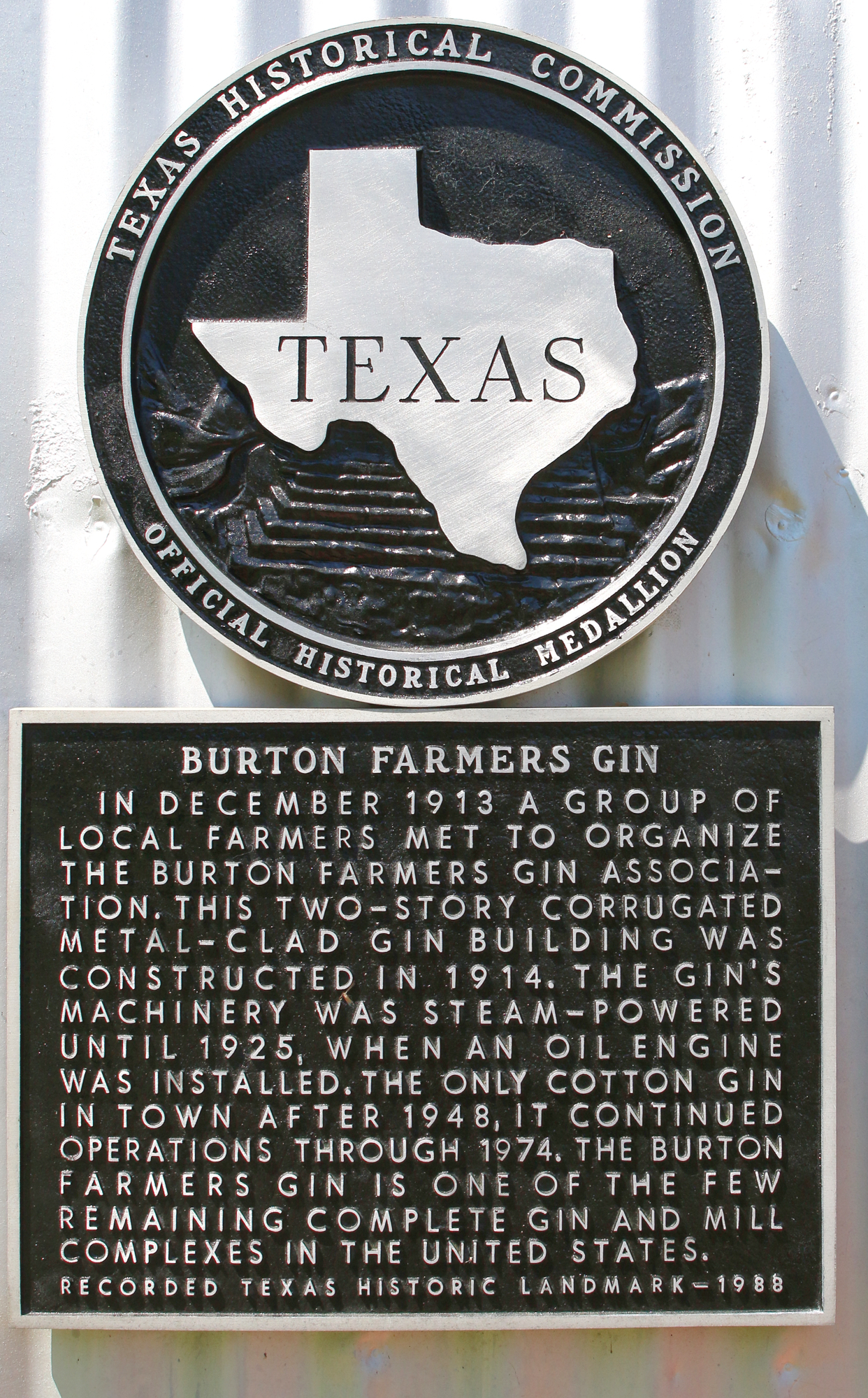

The Texas Cotton Gin in Burton, Texas is the oldest operating cotton gin in America. This gin was founded in 1914. The Burton Farmers Gin ran from 1914 to 1974 and still runs today during its annual Cotton Gin Festival on the 3rd Saturday in April. Have you ever been to a cotton gin?

Thanks to the Washington County Chamber, our family received complimentary access to the tour to share our experience with you.

When my family and I toured the museum and the gin seen in the background, we thought it was pretty fascinating. I have always been a history guy and this was just cool to me.

Ginning is a tough thing to do by hand. Picking the seeds out of the cotton was not easy, my family got to try it. Ginners in China and India made what you see in the above photo. It’s call, the double roller gin. It made ginning the seeds a lot easier than doing it by hand. This was made around the 12th Century.

During our tour, we were each given a small piece of unclean cotton to pick at by hand and my son worked on his piece for an hour! Can you imagine doing that as your job?

This machine is called the Eli Whitney’s cotton engine. It was invented in 1793, by Eli Whitney. What you can’t see is there are little saw blades where the cotton is on the top. As the motor runs, it turns the saw blades and they rip through the cotton taking the seeds out of it to clean the cotton. If you look at the bottom of the machine in the photo you will see the seeds.

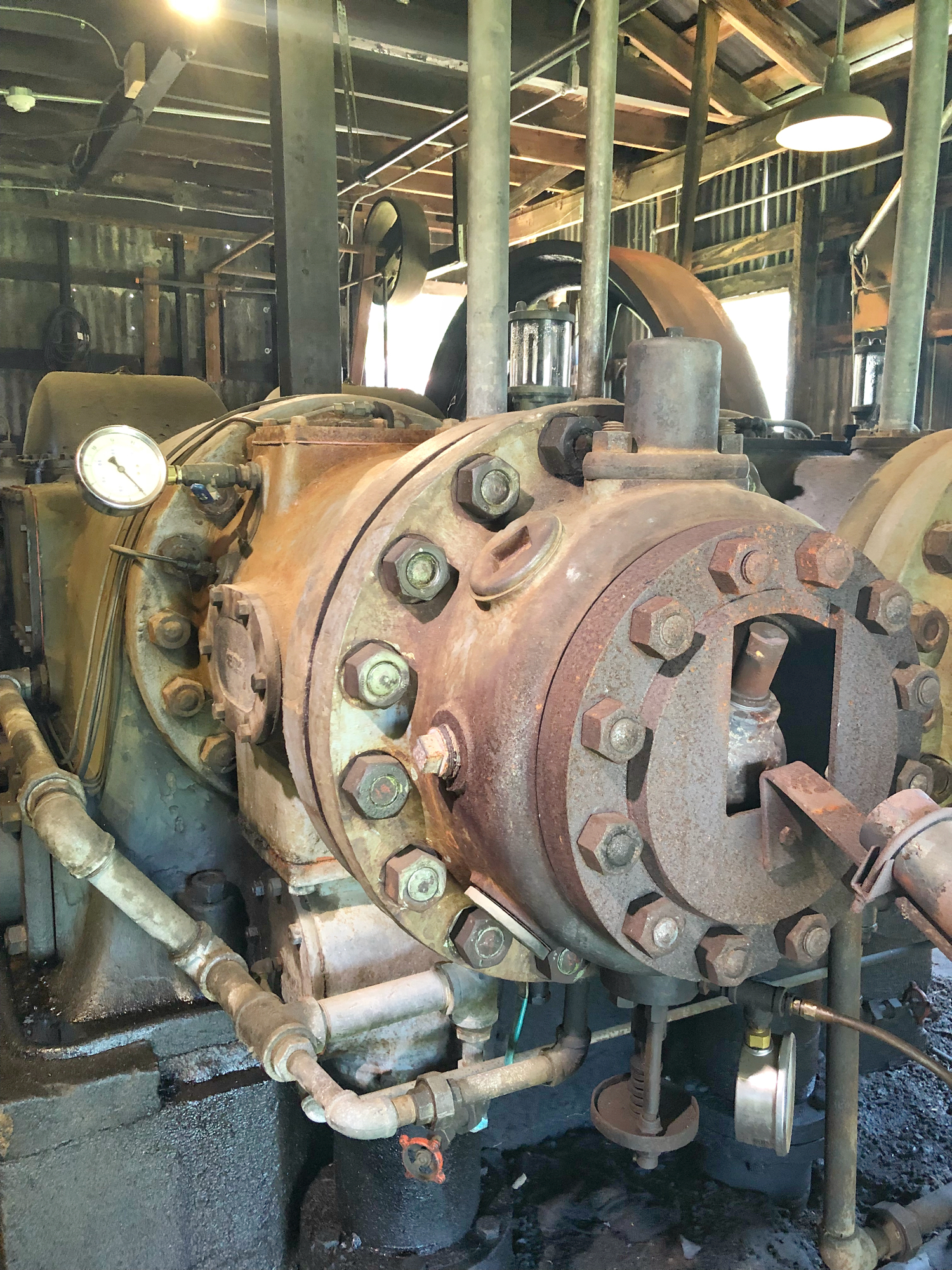

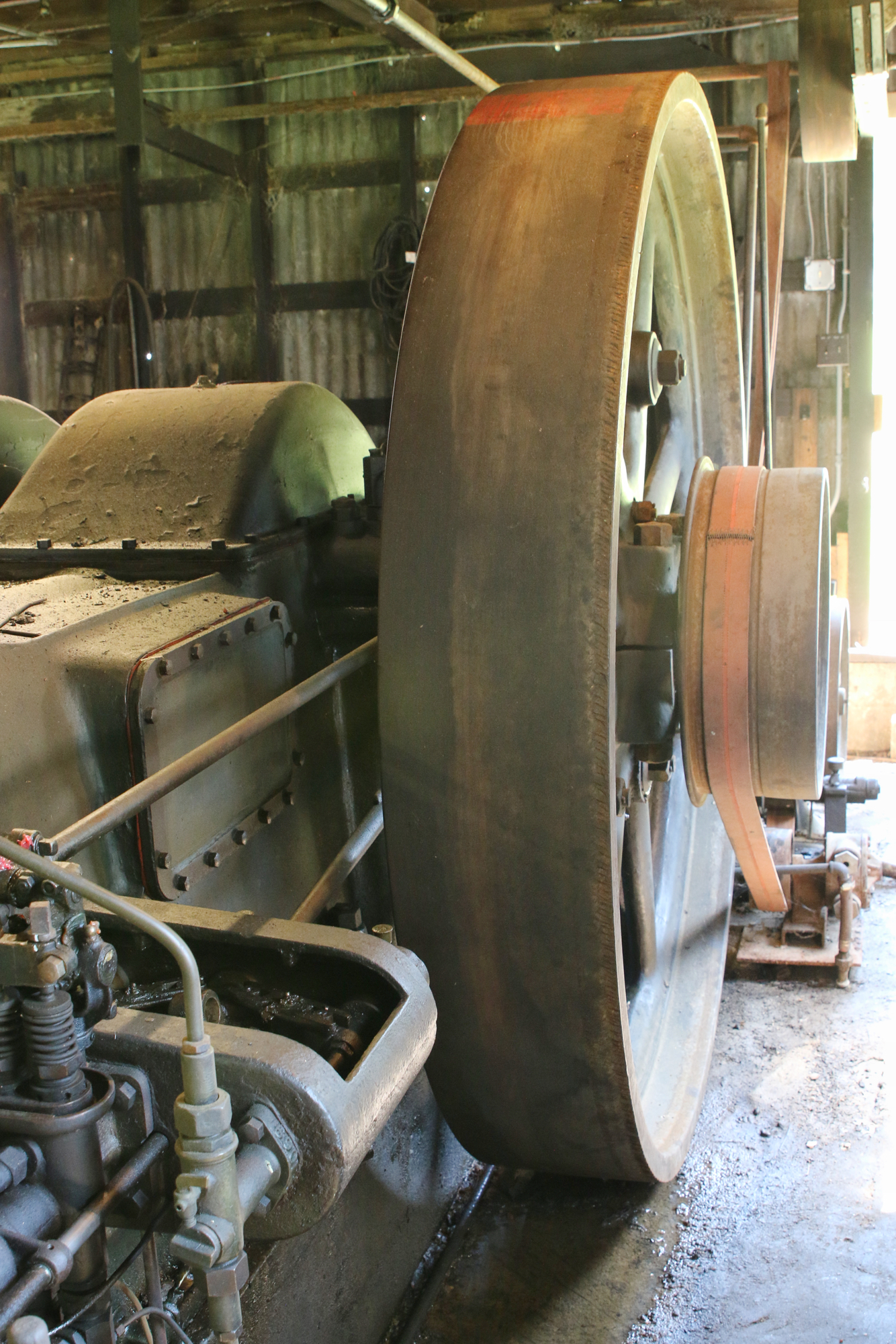

This engine is called the “Lady B”. It is a 1925 Bessemer Type IV Diesel Oil Engine. It is the largest internal combustion engine of its type and it still powers the gin today during the annual Cotton Gin Festival.

I wish we visited the Lady B during the Annual Cotton Festival because I really wanted to hear this beast run. When I walked into the engine room, the smell of the old diesel oil engine made me stop and take a deep breath. I just loved that smell. You engine guys will know what I mean!

Just like the hand powered gin and Mr. Whitney’s gin, this Lummus 5/80 gin made ginning cotton even faster. There were multiple ones that took seeds out of the cotton to get it ready for sale.

Here you can see how part of the Lummus gin worked by separating the cotton and seeds.

When the cotton was stripped of its seeds this is where the cotton ended up. The cotton would then be placed into this wooden box where it would be compressed to make a 500-pound bale of cotton.

The floor then would turn and the other box could then be filled with cotton as the previous box of cotton would then be strapped with metal straps to hold the compressed cotton. After all, what do you think is going to hold that 500 pounds of cotton together?

Here is what 500 pounds of cotton looks like after it has been strapped.

Texas Cotton Gin Museum Fun Facts

One bale of cotton is approximately 500 pounds. Out of the 500 pounds of cotton, the textile industry can produce:

- 300 pairs of jeans or

- 1217 men’s t-shirts or

- 764 men’s dress shirts or

- 484 men’s trousers or

- 896 woman’s blouses or

- 542 woman’s shirts or

- 782 terry bath sets or

- 210 sheets

It is free to visit the Texas Cotton Gin and Museum in Burton. If you take the guided tour it cost $6 an adult and $4 a student. Children under 5 are free. The guided gin tours are daily starting at 10 am and 2 pm. Take your family out to the Texas Cotton Gin and see a great part of history.